Main parameter of Shearing machine

| Model | Thickness | Width | Angle of shear | Depth | Main motor power | Appearance dimension | |

| mm | mm | ° | mm | kw | mm(L×W×H) | ||

| 4×2500 | 4 | 2500 | 0.5-1.5 | 100 | 5.5 | 3000×2000×1850 | |

| 6×2500 | 6 | 2500 | 0.5-1.5 | 125 | 7.5 | 3030×2075×1920 | |

| 6×3200 | 6 | 3200 | 0.5-1.5 | 125 | 7.5 | 3730×2075×1970 | |

| 6×4000 | 6 | 4000 | 0.5-1.5 | 125 | 7.5 | 4530×2075×2080 | |

| 6×5000 | 6 | 5000 | 0.5-1.5 | 125 | 7.5 | 5530×2075×2210 | |

| 6×6000 | 6 | 6000 | 0.5-1.5 | 125 | 11 | 6530×2075×2520 | |

| 7×7000 | 7 | 7000 | 0.5-1.5 | 125 | 11 | 7530×2075×2830 | |

| 8×2500 | 8 | 2500 | 0.5-1.5 | 125 | 11 | 3040×2075×1920 | |

| 8×3200 | 8 | 3200 | 0.5-1.5 | 125 | 11 | 3740×2075×1920 | |

| 12×2500 | 12 | 2500 | 0.5-2 | 125 | 15 | 3110×2575×2210 | |

| 12×3200 | 12 | 3200 | 0.5-2 | 125 | 15 | 3810×2575×2420 | |

| 12×4000 | 12 | 4000 | 0.5-2 | 125 | 15 | 4610×2575×2530 | |

| 16×2500 | 16 | 2500 | 0.5-2.5 | 125 | 22 | 3130×2655×2200 | |

| 16×4000 | 16 | 4000 | 0.5-2.5 | 125 | 22 | 4630×2655×2570 | |

| 20×2500 | 20 | 2500 | 0.5-2.5 | 125 | 30 | 3160×2855×2300 | |

| 20×4000 | 20 | 4000 | 0.5-2.5 | 125 | 30 | 4660×2855×2720 | |

| 25×2500 | 25 | 2500 | 0.5-3.5 | 120 | 37 | 3330×2000×2650 | |

| 25×3200 | 25 | 3200 | 0.5-3.5 | 120 | 37 | 3970×2100×2865 | |

| 25×4000 | 25 | 4000 | 0.5-3.5 | 120 | 37 | 4780×2500×3150 | |

| 32×2500 | 32 | 2500 | 0.5-3.5 | 120 | 45 | 4100×2300×3200 | |

| 32×3200 | 32 | 3200 | 0.5-3.5 | 120 | 55 | 1900×2650×3450 | |

| 40×2500 | 40 | 2500 | 0.5-3.5 | 120 | 75 | 4100×2550×3500 | |

| 40×3200 | 40 | 3200 | 0.5-3.5 | 120 | 75 | 4900×2900×3750 | |

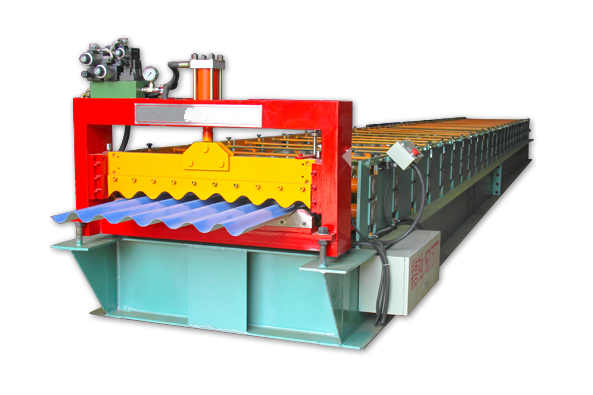

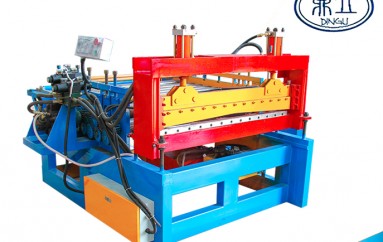

Product information:

Shearing machine is a machine which with a blade relative to another reciprocating linear motion of the shearing blade plate machine. Is borrowed in motion on the blade and fixed lower blade, using reasonable blade clearance, shearing force is applied to the sheet metal of various thicknesses, the sheet material separated by the desired size of the fracture. Shearing machine belong forging machinery in one, the main role is the metal processing industry. Our products are widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automotive, electrical, electronics, decorating, and other industries to provide the required special machinery and complete sets of equipment required.

Characteristic:

First, you can select the machining mode, compared with gas welding cutting, after its processing crystalline phase structure steel fewer changes insurable. Former state certificate of steel is conducive to high-quality processing.

Second, high precision, can reduce waste, scrap, can also reduce the amount of re-processing of cutting, not only improves the plus. Work efficiency, but also helps to reduce consumption.

Third, due to the concentration process can ensure the continuity of batches and production; we can specialize in this technology and using the first. Advanced equipment, greatly raising and lowering

Fourth, allowing users to simplify production processes, increase production levels.