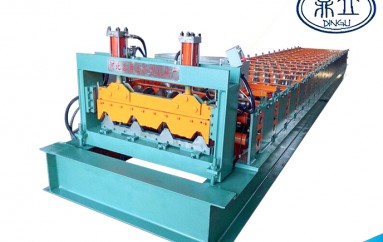

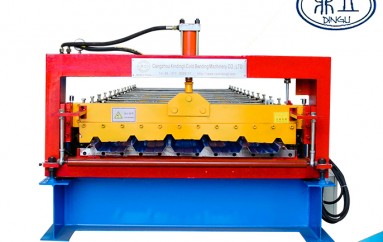

Main parameter of double layer roofing sheet roll forming machine

| Raw material | |

| material spec | colored steel sheet,galvanized steel sheet,aluminium sheet |

| thickness of coil sheet | 0.3-0.8 mm |

| material expand width | 1000mm |

| Efficiency width | 840/850mm |

| Machine details | |

| roller material | high grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material | high grade NO. 45 carbon wrought steel |

| cutting blade | Cr12 mould steel with quenched treatment |

| diameter of shaft | 70mm or as your requirement |

| main frame | 300 H steel |

| forming steps | Up layer:9 rows

Down layer:11rows |

| productivity | 20-25m/min |

| hydraulic station power | 4 KW |

| hydraulic pressure | 10-12MPa |

| controlling system | famous PLC computer control |

| material of cutting table | Cr 12 mould steel with quenched treatment |

| appearance size | 6700mm*1500mm*1510mm |

| hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirements |

| After sale-services | |

| Delivery | 30 workdays after receiving the deposit |

| Warranty | one year warrantly and lifelong technical suport will be kind and

effective provided. |

| Payments | 30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment |

Product information:

Double layer roofing sheet roll forming machine is our factory’s new products. It`s often uesd in the create roof panels or gutters for the purpose of home construction .Double deck Roll forming is a manufacturing process that requires rollers to design something by pressing and rolling it. Our team of technical professionals manufactures this machine by making use of fine grade components with the help of advanced technology in adherence with defined industry norms. To fulfill the diverse application requirements of clients, this Double Deck Roll Forming Machine is offered in a range of technical specifications. Patrons can easily avail this roll forming machine at affordable prices.

Components of Double deck roll forming machine

This double deck machine consists of manual decoiler, roll forming machine, plc control system. Hydraulic part, cutting part, discharge table.

Characteristic

1 High production capacity, A machine capable of producing two types of metal plates.Saves the customer’s production time, improve productivity

2 Easy to fix and operate

3 High operational fluency, beautiful appearance

4 Durability