Main Parameter for Glazed Tile Roll Forming Machine

| Raw material | |

| material spec | colored steel sheet, galvanized steel sheet, aluminum sheet |

| thickness of coil sheet | 0.3-0.8 mm |

| material expand width | 1200mm |

| Efficiency width | 1050 mm |

| Wave height | 25 mm |

| Wave length | 210 mm |

| Machine details | |

| roller material | High grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material | High grade NO. 45 carbon wrought steel |

| cutting blade | Cr12 mould steel with quenched treatment |

| diameter of shaft | 70mm or as your requirement |

| main frame | 300 H steel |

| forming steps | 13 rows |

| productivity | 2-4 m/min |

| hydraulic station power | 4 KW |

| hydraulic pressure | 10-12MPa |

| controlling system | famous PLC computer control |

| material of cutting table | Cr 12 mould steel with quenched treatment |

| appearance size | 7200mm*1500mm*1510mm |

| hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirements |

| After sale-services | |

| Delivery | 30 workdays after receiving the deposit |

| Warranty | one year warranty and lifelong technical support will be kind and

effective provided. |

| Payments | 30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment |

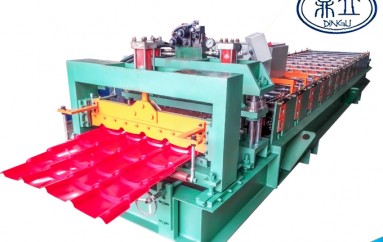

Product information:

Glazed tile has a beautiful appearance, simple and elegant, sophisticated styling, noble taste and other characteristics, can be widely used in garden plants, scenic spots, pavilions, hotels, villas, galleries, resorts, home and other buildings, and beautiful and durable.

The glazed tile roll forming machine products beautiful appearance of smooth, paint pattern uniform, high strength, durable, widely used in industrial and civil buildings, such as factories, warehouses, machine garages, hangars, stadiums, exhibition halls, theaters and other room surfaces and wall.

Components of roll Glazed tile roll forming machine

This glazed tile roll forming machine consists of manual/ automatic decoiler, roll forming machine, plc control system, hydraulic part, cutting part and discharge table.

Characteristic

1. Is made of high strength steel plate for the base material,

and the most advanced design and roll forming. It has excellent structural properties.

2. Glazed tile roll forming machine use less power, saving energy consumption, reducing the cost of production

3. High efficiency, energy saving, production speed, can be used continuously

4. Small volume, light weight, mobile transportation is convenient, small footprint