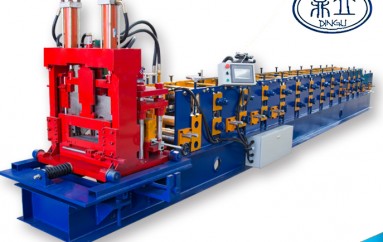

c z purlin roll forming machine

| Raw material | |

| material spec | sheet, galvanized steel sheet, aluminum sheet |

| thickness of coil sheet | 1.0-3.0 mm |

| material expand width | 175-465mm |

| Machine details | |

| roller material | High grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material | High grade NO. 45 carbon wrought steel |

| cutting blade | Cr12 mould steel with quenched treatment |

| diameter of shaft | 70mm or as your requirement |

| forming steps | 12 rows |

| productivity | 15-20m/min |

| hydraulic station power | 4 KW |

| hydraulic pressure | 10-12MPa |

| controlling system | famous PLC computer control |

| material of cutting table | Cr 12 mould steel with quenched treatment |

| appearance size | 6100mm*1150mm*1510mm |

| hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirements |

| After sale-services | |

| Delivery | 30 workdays after receiving the deposit |

| Warranty | one year warranty and lifelong technical support will be kind and

effective provided. |

| Payments | 30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment |

C/Z pulin roll forming machine

C purlin roll forming machine is one of the basic type on tile roll forming machine. It was widely used in the Standard Steel plant and simple steel house. Especially the hydraulic power system’s using makes it faster than other ordinary machines.

Components of C/Z purlin roll forming machine

This C purlin roll forming machine consists of hydraulic decoiler, straightening and roll forming M/C,PLC control system, hydraulic pressing&cutting, and production stand.

Characteristic

1. It’s made of high strength steel plate for the base material,

and the most advanced design and roll forming. It has excellent structural properties.

2. Quality Materials to meet fire code requirements.

3. High efficiency, energy saving, high speed and can be used continuously