GENERAL CONSTRUCTION

We seek to get involved early in the design phase so that we can manage the project more efficiently, provide effective building solutions, and identify challenges early on to mitigate design changes after construction commencement.consectetur adipisicing elit sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim minim veniam ostrud exercitation.

This involves detailed pre-construction planning crucial to successful construction and on-time delivery, and allows the client and team a clear pathway to the bidding process, construction phase, and through to completion.

Information:

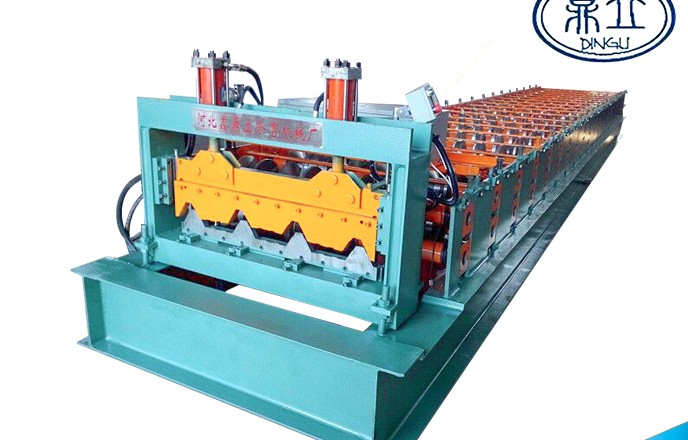

The car panel suitable for wide plate forming, It has beautiful forming, high degree of automation, simple operation, and long life, the production speed can up to 15-20m / min, high utilization of raw materials, fixed-length accuracy. The carriage board roll forming machine is mainly used for the production of car plates, container board and so on.

Components of carriage board roll forming machine

This car panel roll forming machine consists of manual/ automatic decoiler, roll forming machine, plc control system, hydraulic part, cutting part and discharge table.

Characteristic

1. Simple structure, beautiful appearance, because the machine uses steel structure, the overall processing after welding, so the structure is simple and reasonable, strong carrying capacity, smooth and reliable operation.

2. The equipment important components are made of well-known enterprises in domestic accessories, so as to effectively guarantee the performance of the device.

3. Using automatic fixed-length cut, precise positioning, neat appearance and without distortion.

4. Equipment installation and debugging convenient, easy to operate, both for factory production, or can be transported to the construction site manufacture.

5. Low equipment noise, no pollution, low consumption.