Main parameter for Roll forming machine

| Raw material | |

| material spec | colored steel sheet, galvanized steel sheet, aluminium sheet |

| thickness of coil sheet | 0.3-0.8 mm |

| material expand width | 1000mm |

| Efficiency width | 836mm |

| Wave height | 18mm |

| Wave length | 76mm |

| Machine details | |

| roller material | High grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material | High grade NO. 45 carbon wrought steel |

| cutting blade | Cr12 mould steel with quenched treatment |

| diameter of shaft | 70mm or as your requirement |

| main frame | 300 H steel |

| forming steps | 12 rows |

| productivity | 20-25m/min |

| hydraulic station power | 4 KW |

| hydraulic pressure | 10-12MPa |

| controlling system | famous PLC computer control |

| material of cutting table | Cr 12 mould steel with quenched treatment |

| appearance size | 6100mm*1500mm*1510mm |

| hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirements |

| After sale-services | |

| Delivery | 30 workdays after receiving the deposit |

| Warranty | one year warranty and lifelong technical support will be kind and

effective provided. |

| Payments | 30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment |

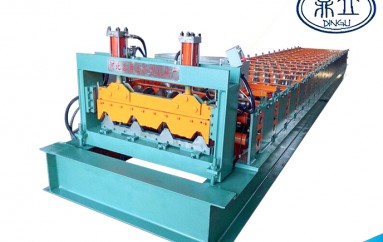

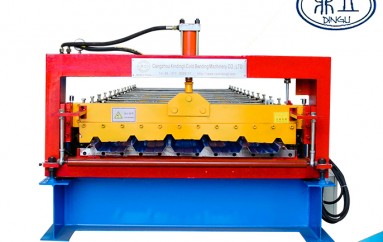

Product information

These machines are used for producing steel roofs and are so very durable in nature. These are highly demanded in market due to their extensive features such as rigid construction, fine quality and hassle free performance. Different roof panel machines can produce different shapes of steel roof, wall sheets according to the clients’ profile drawings and requirement. Steel roof, wall sheets are new building materials with various thickness and colors.They are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition centers, etc.

Components of Corrugated roll forming machine

The complete corrugated roof panel machine line includes decoiler, main machine, computer controlling system and run out tables. Our machines are equipped with a computer controlling system. We simply program the pieces and length we need in the computer and the wave panel machine produces it automatically.The machines are easy to operate and running stable.

Characteristic

1 low cost, Easy to fix and operate

2 short building period

3 re-cycle use

4 beautiful appearance

5 light weight but high strength.