Advantage of Roll Forming Machine

- November 20, 2015

- Posted by: chinarollingmachine

- Category: KNOWLEDGE

Perhaps its points of interest exceed burdens, and possibly others has inverse thought. What’s more, at present metal roll forming machine is generally utilized. What’s more, metal material of cold roll forming process additionally bit by bit show up in the business sector. They are principally utilized as a part of metallurgy, car, home machines, building materials, metal items and different businesses.

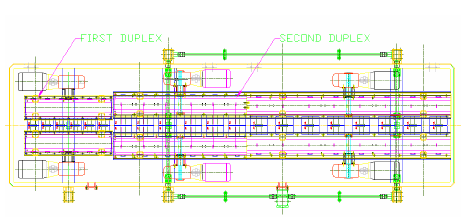

For instance, color steel roll forming machine, this item is utilized as a part of different mechanical workshop, distribution center rooftop etc, and the upsides of the creation has high crests and solid power. Covering sheltered and dependable establishment, water aversion and imperviousness to the hurricane and the hardware has trademark solid of execution. The production of the color steel tile press move framing machine producer has tackled the rooftop spillage issue of traditional weight plate arrangement, and with swelling machine it can make no pillar curve rooftop. The key of the machine parts utilizes numerical control machining, granulating fine crushing, wire slicing thus on to machine finely. Besides, receives PLC control, and understands the web following and synchronous cutting. Outline and fabricate of gear generation is perfect to the point that has the upsides of high return, advantageous operation, low power utilization.

In addition, advancement of another era of embellishment machine has rapid, steady, protected, low clamor, stable qualities. Molding machine possesses precision powder add filling system . Fully automatic machine, hydraulic lifting. . At the point when powder the bucket is going to complete, include powder machine gets arranges naturally to include powder. Outfitted with two arrangements of established carbide roll can guarantee the typical utilization of 30 years. Taking care of the demand of powder which is content from 10% to 60%, conforming coolly, and it understands accuracy control powder. Factory with the host under synchronous pace, the powder is steady and precise.

Molding machine commonly is known as the cold bending forming machine, is a progressed, proficient plate metal shaping innovation, English name is called roll shaping. Presently coated tile move shaping machine is well known, and it has above Excellencies.

A few individuals may think the cost of cold roll forming machine. From my viewpoint, the business sector is uncalled for that you must open your eyes to pick your truly what you need. What’s more, don’t effortlessly trust the net on the web, on the off chance that you truly require it, to the extent I’m concerned, you would be wise to meet the host of the generation and survey some exploration if there should arise an occurrence of being swindled.

Cold bending forming technology likewise has been generally utilized, very proficient and helpful creation takes numerous risks to the improvement of numerous commercial enterprises, however relatively few individuals know the rooftop board move shaping machine, its center innovation is had just by a couple individuals. I’m stir individuals likewise pointed out for associates more the improvement and innovation advancement of cold bending forming