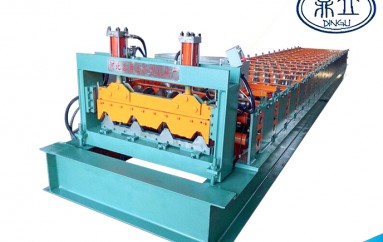

Main parameter for Double decker roll forming machine

| Raw material | |

| material spec | colored steel sheet,galvanized steel sheet,aluminium sheet |

| thickness of coil sheet | 0.3-0.8 mm |

| material expand width | 1000mm |

| Efficiency width | 820/840mm |

| Machine details | |

| roller material | high grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material | high grade NO. 45 carbon wrought steel |

| cutting blade | Cr12 mould steel with quenched treatment |

| diameter of shaft | 70mm or as your requirement |

| main frame | 300 H steel |

| forming steps | Up layer:13 rows

Down layer:11rows |

| productivity | Up layer:2-4m/min

Down layer;20-25m/min |

| hydraulic station power | 7.5 KW |

| hydraulic pressure | 10-12MPa |

| controlling system | famous PLC computer control |

| material of cutting table | Cr 12 mould steel with quenched treatment |

| appearance size | 8500mm*1500mm*1510mm |

| hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirements |

| After sale-services | |

| Delivery | 30 workdays after receiving the deposit |

| Warranty | one year warrantly and lifelong technical suport will be kind and

effective provided. |

| Payments | 30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment |

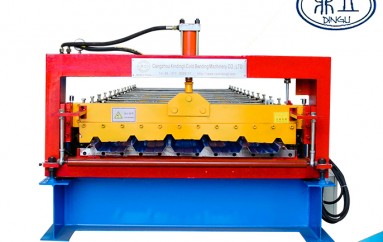

Product introduction

Tile press equipment may also be referred to roll cold forming, that is, in a row in series forming mill, contact through the metal plate and the metal strip, sequentially to bend, the plates were processed into the desired cross-sectional shape of the plastic processing method.

Application

The roof tile roll forming machine is widely used in industrial and civil architecture, warehouses, large span steel structure housing the roof, walls and interior and exterior decoration and so on.

Characteristic

The machine has lightweight, high strength, color-rich, convenient construction, earthquake, fire, rain, long life, maintenance-free characteristics.

(1) The roof tile roll forming machine using a high level of automatic control software, production information management.

(2) The entire unit automation control system uses highly integrated network, enabling superior performance automation systems.

(3) The pressure-watt machine also has the operation, maintenance, maintenance and mechanical commissioning mold advantages of easy replacement.