Main parameter for Cnc sheet metal forming machine

| Raw material | |

| material spec | colored steel sheet, galvanized steel sheet, aluminum sheet |

| thickness of coil sheet | 0.3-0.8 mm |

| material expand width | 1000mm |

| Efficiency width | 840mm |

| Wave height | 25mm |

| Wave length | 210mm |

| Machine details | |

| roller material | High grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material | High grade NO. 45 carbon wrought steel |

| cutting blade | Cr12 mould steel with quenched treatment |

| diameter of shaft | 70mm or as your requirement |

| main frame | 300 H steel |

| forming steps | 11 rows |

| productivity | 20-25m/min |

| hydraulic station power | 4 KW |

| hydraulic pressure | 10-12MPa |

| controlling system | famous PLC computer control |

| material of cutting table | Cr 12 mould steel with quenched treatment |

| appearance size | 5700mm*1500mm*1510mm |

| hydraulic oil | 40# hydraulic oil |

| Electric tension | 380V 50 Hz 3 Phase or as your requirements |

| After sale-services | |

| Delivery | 30 workdays after receiving the deposit |

| Warranty | one year warranty and lifelong technical support will be kind and effective provided. |

| Payments | 30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment |

Product information:

Roof panel are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets, shopping malls, trade markets, stadiums, holiday villags, sanatoriums, hotels, villas, residences, and different kinds of greenhouses. And roof panel machine also have other names, such as IBR sheet roll forming machine, roofing panel making machine, and some countries also named corrugated sheet machine.

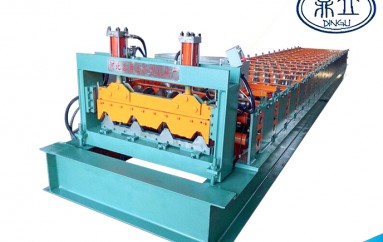

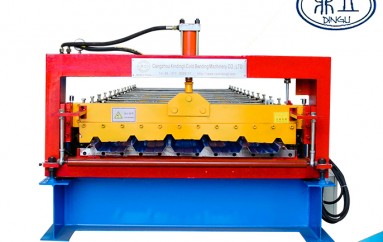

Components of Trapezoidal / ibr Roof panel machine

The components of this roof panel machine are: manual/automatic decoiler, roll forming machine, plc control system, hydraulic part, cutting part and discharge table.

Characteristic:

1. High speed

2. Low noise,

3. Good performance and low production cost.

4. Easy to operate